I stop in Trujillo every time I touchdown in the country. Luckily for me, the City of Trujillo is known as the capital of footwear in Peru. Now, added to that list of places to visit is the footwear district of El Porvenir, which I visited for the first time during my 2024 trip.

Heading from the hotel, we were told to keep our guard up when walking around the manufacturing district in EL Porvenir. This is due to many thieves and armed criminals in the area, a situation which only worsened because of the economic drought the province suffered during Covid. Interestingly enough, on one of our rides back from the footwear district, the taxi driver informed us that there was a daylight shooting in one of the fanciest areas of Trujillo, proving you can never be too careful. Luckily for us, our ventures to the district were all glowingly positive.

From craftsmen who had worked in the district for over thirty years to ladies who sold footwear components in bulk, you could find each stage of the process. Large sheets of leather all rolled up next to one another would eventually become the uppers of smart shoes worn by the older Peruvian man, a model that seemed to forgo the typical decadence of the European Brogue.

An elderly lady sorting bundles of loose laces stands under a selection of tongue labels from all the most popular brands. She had likely been surrounded by footwear long before I was born, a humbling thought for any shoe dog out there. That said, I don’t think she was lost in thought over any pending eBay bids or going through her mental checklist of ‘grails’, that sort of thing did not hold weight around her stall.

Much of the equipment allowed for repairs or alterations such as the pair of knockoff “AAICS” shoes that were being widened for a customer, as the average Peruvian tends to have a wider foot. Here the machine would introduce a wider metal last to slowly stretch the forefoot portion of the upper and create extra room in the toebox. This was a natural part of the process with no sight of #sustainability posters stuck to the walls. Getting the most out of your resources was just simple logic.

Laces, dubraes and buckles were also available by the bulk load, each vendor willing to bargain with you depending on the size of your order. My Mum picked up 10 sets of flat laces to go with her favourite New Balances, this only set her back 20 Solles or £4.

I on the other hand managed to pick up a small bundle of Nike lace dubraes for less than 50p, a harrowing reminder of how much brands truly overcharge for footwear in the UK. Sure shipping and marketing costs add to the overall retail price tag, however sneakerheads who are easily blown away by extra detailing and packaging would be surprised at the pence per unit difference that these manufacturing costs would actually make. Two extra sets of laces are always an appreciated touch, costing the brand perhaps 10p in addition but a detail that during the video review stage could help tip customers over the edge.

For a minute I thought about going full fugazi on my recently purchased Nike PS8s by adding an extravagant Lacoste or Barbie dubrae but refrained, opting for a simple set of Nike ones instead.

Midsoles were available by the bulk, including the Predator or Air Force 1 option shown in-hand. Did I want a set of murdered-out AF1 midsoles to take back to the UK? Yes, of course I did. Although that would have been a completely unnecessary purchase, not even bothering to ask what the cost price was.

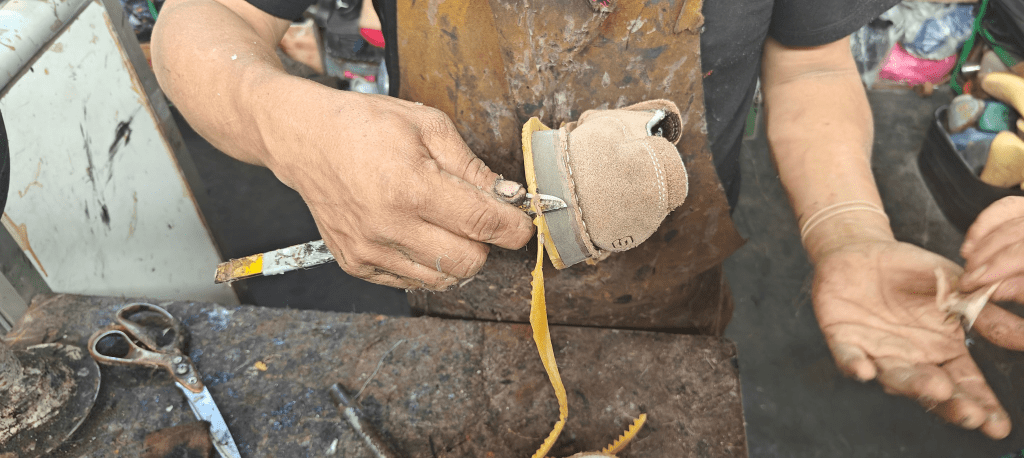

I approached a gentleman cutting off the excess outsole with a sharp blade, all the while making sure not to capture his face in the photo so as to respect his privacy. This did not sit well with him as he wanted his moment in the spotlight, a form of recognition for surely was a line of work he had spent decades in.

Another man around the corner was operating what he told me was a welt stitching machine that had been running since the ‘80s. Punching a needle between the leather midsole and upper, he continued to produce a set of light tan work shoes that would find their way onto the feet of the businessmen of Trujillo.

I had only seen this level of workmanship in YouTube videos or briefly caught the process at my local Thimpsons. Seeing it at the heart of the manufacturing district of El Provinar was a different feeling altogether. A behind-the-scenes look at the creation process of the shoe, an object that continues to captivate my everyday life.

Often romanticised by the industry via New Balance Made in UK campaigns of adidas’ Made in Germany editions, there was just as much experience and knowledge held within the hands of those who worked at El Porvenir. Of course, without the marketing budget and expensive film crew, these stories will continue to go unheard.

My second visit to the district was a few weeks later. I would return hoping to find an elderly lady called Rosa who was the only person able to make a Last for me. The other vendors would all point towards the direction of her shop, each wild goose chase leaving me empty-handed.

“She should be here in the next hour”

“Oh Rosa starts after lunchtime”

“She only works weekends now”

These were the various replies we were told by those who worked there, all of which repeatedly led towards Rosa’s blue shop shutters. While the area was full of skilled workers, she was the only person left who was able to make a custom wooden last. The plastic lasts were widely available for purchase but I only had my eyes set on the traditional wooden ones.

They would make me feel like a man from the 19th century who had just carted in from the countryside into the bustling city. Wearing a waistcoat and top hat, I would stroll into the cobblers ready to collect my new leather shoes for a friend’s wedding so I could look the part. Yet in reality, I would get the train to Slough where I would turn up in my second-hand Balley Loafers which might be made in France but are also in dire need of re-welting (a tangent but a necessary one).

While you can get a wooden Last made in England, these will run you back an eye-watering amount. For example, John Lobb is a centuries-old bootmaker shop in London that provides this service. This age-old reputation does come with a high price tag, so unless you have a budget of £5000, you can put those dreams on pause.

I am sure the shop gains custom for many a wealthy banker and financial director, but my shoe-writing budget has a way to go before it can stretch that far. I am not complaining though, as each cobbler spends on average 2-4 days per shoe, with the more skilled ones creating up to 5 shoes per week. Calculating the manhours behind each pair and the rarity of those skills in today’s world, the price is sadly justified.

In one last attempt, I stumbled across one of the older-looking shops. A stack of wooden Lasts across his shelves gave me a slither of hope, an episode of Top Cat playing from his old box Television.

“Ahh no sorry, I don’t make them. You can purchase one of these though, I’ve got a size 8 you can buy”, Close but no cigar. They also weighed a tonne and space in my return luggage was getting smaller by the day.

I left the district with no wooden Last. That is not to say the time was wasted, as each minute witnessing the manufacturing process was time well spent. It is hard to tell if I would return to the district during future trips, with the mysterious character of Rosa all but lost to the magic of El Provinar (I wouldn’t even know how much she would have charged me either as a UK12 is almost unheard of within that space). Perhaps they will tell her Bigfoot was looking for her, although I would be surprised if I had done enough to earn that reputation.

If you are in Trujillo and love shoes, then I would say it is worth visiting El Provinar provided you are not going alone. Also, do not take your phone out too much and hide valuable items like your watch or chain. Otherwise, enjoy the behind-the-scenes process and maybe pick up some laces or lace dubraes while there!